Cam Operated Directional Valves

These valves may be used to shift the direction of oil flow by depressing the spool by way of a cam.

Double Locking Check Valve

These Check Valves are flow in one direction and pressure flow in reverse direction, until operated by pilot operated pressure to allow reverse flow. The specific cracking pressure required to open the valve to allow free flow direction.

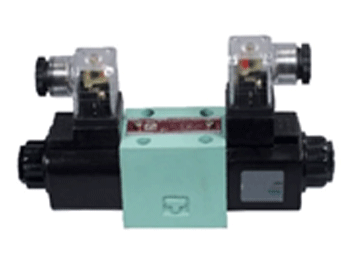

DSG-03 Series

These are epoch-making solenoid operated valves of high pressure, high flow which have been developed incorporating a unique design concept into every part of the valve including the solenoid. With wet type solenoids, these valves ensure the low noise and the long life, moreover, ensure no leakage of oil outside of the valves.

Manually Operated Directional Valves

These valves may be used to manually shift the spool position and change the direction of oil flow.

Pilot Controlled Check Valves

These check valves allow flow in one direction and prevent flow in the reverse direction, until operated by pilot pressure to allow free reverse flow. The specified cracking pressure is required to open the valve to allow free flow direction.

Pilot Operated Directional Valves

These valves are composed of a solenoid operated pilot valves and a pilot operated slave valve. When a solenoid is energised the pilot valve directs the flow to move the spool of the slave valve, thus changing the direction of flow in the hydraulic circuit. High Pressure High Flow High pressure [315 Kgf/cm2 ] along with high flow means compact system design. Lower pressure Drop System energy saving increased as pressure drop of each valve has greatly reduced.

Poppet Type Directional Valves

These are Solenoid Operated Directional Valves of No Leak Type developed with the aim of responding the demand of the age including energy saving. Because these valves are of no leak type, they allow the low viscosity hydraulic fluids to be used as well as the circuit construction which cannot be used by the conventional spool type directional valves because of too much internal leak of pressure oil. The use of the low viscosity hydraulic fluids reduces the pressure loss which can arise from the pressure resistance of the hydraulic fluids, leading to the system energy saving.

Poppet Type Two-Way Valves

These valves are used for opening/closing oil path by having the poppet valve operated according to electric signal via solenoid. Because these are of poppet type, there is no hydraulic lock and the internal leakage can be greatly reduced.

Solenoid Operated Directional Valves

The valves are much more compactly manufactured but enjoy a maximum operating pressure of 25 MPa and a maximum flow rate of 15 L/min, while contributing further to a space saving requirement. Moreover, using wet armature solenoids, the valves ensure the long life and low noise.